Product added to cart

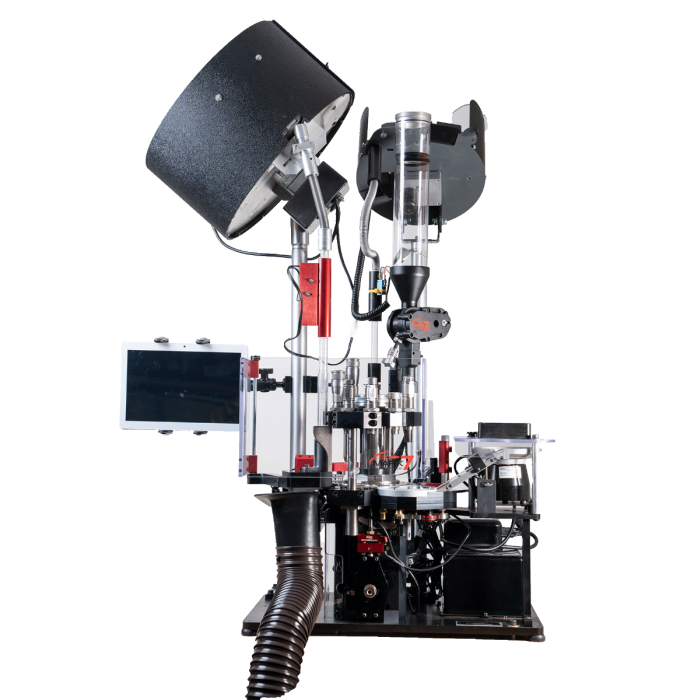

The Revolution®

In Stock.

$13,249.95

In Stock.

SKU

101-1176

FREIGHT WILL BE ASSESSED AND CHARGED AT TIME OF SHIPMENT

Mark 7’s 10 Station Revolution® Loading Platform is designed for commercial ammo production. Whether you're producing tens of thousands of rounds of ammunition per day or processing brass for resale, this machine was built to handle the job. The Revolution Press is built to be easily configured for brass processing, for loading with pre-primed brass, for priming, or for full loading capabilities. Order your Revolution with only the functionality you need and retain the ability to upgrade for full reloading whenever you like!

The Loading Revolution’s are available in calibers ranging from 380 ACP up to 308 Winchester with a few other larger options. The Processing and Priming Revolutions have options ranging from 380acp to 338LM. Switching between calibers is fast and easy using Mark 7’s Caliber Conversion Kits.

Depending on configuration, the press comes complete with an Onboard Collated Priming System, a 14” Case Feeder, a Digital Powder Measure, and a Mr. Bullet Feeder Pro. The Revolution comes standard with Digital Clutch Adjustment, TorqueSense TM Technology, and digital sensors to warn you of any potential problems at each step of the loading process before they can cause damage or downtime.

To create the perfect system to meet your needs, we'd like to have a quick conversation with you to learn more about your business model and what calibers you have in scope. Some of our accessories can be shared between calibers, and we have several press configurations that are optimized for different loading needs. Please give us a call, and we’ll work together to create the ideal custom package for you!

Call 1-888-4MARK77 (1-888-462-7577) to speak with a Mark 7 Sales Specialist to build the perfect system to meet your loading needs, or Email [email protected] Commercial Financing Available

Revolution Configurations

Processing

(#101-1176-01)

Loading without Priming

(#101-1176-02)

Priming

(#101-1176-03)

Full Loading

(#101-1176-04)

Processing

Starting at

$8,749.95

Revolution - Direct Drive

No Priming

14” Case Feeder

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• DecapSense

• SwageSense

Accessories*

($1,009.65)

• FW ARMS Decapper

• FW ARMS Swage Station Foot

• Carbide Sizing Die

• Heavy Duty Tool Head Jack Bolt

• Trimmer xPress

• Carbide Trimmer Die

• Machine Cover

• Tool Head Stand

*Fully Equipped

$9,759.60

Part #101-1176-01

Loading (Without Priming)

Starting at

$10,674.95

Revolution - Direct Drive

No Priming (Spacer Housing Installed)

14” Case Feeder

Digital Powder Measure

Mr. Bullet Feeder Pro

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• Powder Check

• Bulletsense

Accessories*

($619.80)

• Ultimate Die Pack

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

*Fully Equipped

$11,294.75

Part #101-1176-02

Priming

Starting at

$10,874.95

Revolution - Direct Drive

Automated Priming

14” Case Feeder

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• SwageSense

Accessories*

($345.80)

• Carbide Sizing Die

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

*Fully Equipped

$11,045.75

Part #101-1176-03

Full Loading

Starting at

$13,249.95

Revolution - Direct Drive

Automated Priming

14” Case Feeder

Digital Powder Measure

Mr. Bullet Feeder Pro

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• Decap Sense

• Swage Sense

• Powder Check

• Bulletsense

Accessories*

($554.85)

• Ultimate Die Pack

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

*Fully Equipped

$13,869.75

Part #101-1176-04

Processing

Loading (Without Priming)

Priming

Full Loading

Starting at

$8,749.95

Revolution Direct Drive

No Priming (Spacer Housing Installed)

14" Case Feeder

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• DecapSense

• SwageSense

Starting at

$10,674.95

Revolution - Direct Drive

No Priming (Spacer Housing Installed)

14” Case Feeder

Digital Powder Measure

Mr. Bullet Feeder Pro

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• Powder Check

• Bulletsense

Starting at

$10,699.95

Revolution - Direct Drive

Automated Priming

14” Case Feeder

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• SwageSense

Starting at

$13,249.95

Revolution - Direct Drive

Automated Priming

14” Case Feeder

Digital Powder Measure

Mr. Bullet Feeder Pro

Included Sensors and Accessories

• Offload System

• Remote Stop

• Primer Orientation Sensor

• DecapSense

• SwageSense

• Powder Check

• Bulletsense

Accessories*

($1009.65)

• FW ARMS Decapper

• FW Arms Swage Station Foot

• Carbide Sizing Die

• Heavy Duty Tool Head Jack Bolt

• Trimmer Xpress

• Carbide Trimmer Die

• Machine Cover

• Tool Head Stand

Accessories*

($804.85)

• Ultimate Die Pack

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

Accessories*

($345.80)

• Carbide Sizing Die

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

Accessories*

($619.80)

• Ultimate Die Pack

• Heavy Duty Tool Head Jack Bolt

• Machine Cover

• Tool Head Stand

*Fully Equipped

$9,759.60

*Fully Equipped

$11,294.75

*Fully Equipped

$11,045.75

*Fully Equipped

$13,869.75

Part #101-1176-01

Part #101-1176-02

Part #101-1176-03

Part #101-1176-04

*Recommended Accessory Package Optional

*Recommended Accessory Packages Optional

CNC Billet Tool Head

Station 1: Case Feeding

Station 2: Sizing and Decapping

Station 3: Swage/Case trim

Station 4: Primer Seat

Station 5: Case Flare/Neck Expansion

Station 6: Powder Drop

Station 7: Powder Check

Station 8: Bullet Dropper

Station 9: Seating

Station 10: Crimping

Motorized Powder Measure

• Accuracy ±0.1 grain

• 5,000 grain capacity

• Integrated powder screen

• Proven drum and metering cylinder design

• Electronic double charge protection

• Optimized for high speed operation

• Works smoothly with most flake and spherical powder types

• High capacity powder reservoir

• Manual setup mode for quick charge adjustment

14" High Speed Case Feeder

• Industrial grade 14" Case Feeder supplies cases quickly and reliably

• Large capacity bowl means less frequent refills

• Can easily be configured for different calibers

Priming System

Onboard collated priming provides consistent, reliable priming you can depend on

Sensors

• DecapSense: Detects a spent primer that’s been decapped from the case

• SwageSense: Detects ringers or any other primer pocket obstruction

• Primer Orientation Sensor: Detects primer pocket depth, will stop machine if primer is missing, upisde down or not seated to the correct depth

• Digital Powder Check: Verifies powder charge

• BulletSense: Verifies bullet has been properly dropped into case.

10" Tablet

• 10" HD Display

• On the fly adjustments including speed, dwell & index

• Bottom slow down

• Display for speed and rounds made

• Can turn sensors on and off

Whether you are loading tens of thousands of rounds of ammunition per day or processing brass for resale, Mark 7’s 10 Station Revolution® Progressive Press has you covered. The Revolution platform supports 16 calibers from 380 Auto up to 308 Win and can produce up to 3500 rounds per hour at maximum speed. Switching between calibers is fast and easy using Mark 7’s Caliber Conversion Kits.

The Revolution comes complete for continuous loading with an Onboard Collating Primer System, 14” Case Feeder, Mr. Bullet Feeder Pro®, and Digital Powder Measure. The Direct-Drive System comes standard with a digital clutch & TorqueSenseTM integrated, and Mark 7 offers a full suite of cutting-edge sensors designed to halt press operation at the first sign of trouble, preventing damage and downtime.

FEATURES

- Outputs up to 3500 Rounds Per Hour

- 10-Station Tool Head, Accepts Most Dies

- Onboard Automated Primer Collator

- 14” Case Feeder (included as standard)

- Mr. Bulletfeeder Pro (included as standard)

- Motorized Powder Measure

- Fully Automated, Digital Control

- Commercial Grade, CNC Steel & Aluminum

- Supports 1-Pass Rifle/Pistol Loading

- Works on New & Once-Fired Brass

- Ultra-Smooth Direct Drive Powertrain

- Precision Shell Plate Movement

- Free Downloadable Software Updates

- Support & Tech Help Included

- 1-Year Manufacturer’s Warranty

AVAILABLE SENSORS & ACCESSORIES

- DecapSenseTM

- SwageSenseTM

- Primer Orientation Sensor

- PowderCheckTM Sensor

- BulletSenseTM

- Remote Stop

- Machine Guard with Auto-Stop Feature

Just processing brass?

Order a Revolution Press with only the functionality you need and retain the ability

to upgrade for full reloading whenever you like!

Why Choose Mark 7?

- Comprehensive and affordable in-house and field training available to make YOU the expert.

- Quick-change between calibers at a fraction of the cost of other commercial loading machines.

- Extremely small footprint, and the system works with most industry standard dies.

- 1-year Limited Warranty, with the ability to add on a powerful Service Agreement.

- Mark 7’s Master Technicians are only a phone call away for support of your equipment.

- Additional Calibers are always being added to satisfy market demand.

- Mark 7 products are backed by Lyman® Products, with over 140 years in the firearms & ammo industry.

Specs and Dimensions

The Mark 7 Revolution comes mounted on a machined solid aluminum baseplate with assembled dimensions of 48” high, 20” wide, and 15” deep (122cm x 51cm x 38cm). Some assembly is required. The Revolution Reloading Platform weights approximately 125 lbs. (57 kg). The press ships in an IPCC-rated wooden crate for maximum protection in transit.

| SKU | 101-1176 |

|---|---|

| Number of Die Stations | 10 |

| Caliber Range | 380 Auto to 308 Win |

| Rounds per Hour | Up to 3500 |

| Drive System | Direct Gear Drive |

| Priming System | Onboard Primer Collator |

| Type of Case Feeder | 14" metal construction, up to 5800 rph |

| Type of Powder Measure | Digitally Controlled |

| Bullet Feeder | Mr. Bullet Feeder Pro |

| Digitally Controlled | Yes, microprocessor monitored and controlled |

| Sensors Included | Torque and Jam Sense (additional sensors optional) |

| Machine Weight | ~100 lbs. |

| Dimensions | 28" x 15" x 45" |

Write Your Own Review

No special tools are needed, but a good Allen wrench set is recommended. It will take about an 1 hour to 90 minutes to get the press set up* meaning the press is physically set up but not ready to load on: that will take another 1 to 2 hours. The necessary steps are:

- Install the sensors

- Set up and adjust the bullet feeder and case feeder

- Set dies

- Set the sensors

- Set powder measure charge, etc...

In all, you should expect to spend 3+ hours to install the press and all sensors.

The ease and time required to change calibers depends on both your primer size and level of experience. Small calibers can take as little as 30 minutes or less with all necessary accessories. Small to large caliber or large to small caliber changes could take up to an hour depending on the number of pieces changed.

- The Rev is our flagship/workhorse press that comes standard with a larger 14” case feeder, Mr. Bullet feeder pro, digital powder measure, and commercial vibratory priming system.

- Emphasis on the “commercial grade” accessories here

- This is a direct drive unit that is extremely smooth in operation and designed to surpass that coveted million round mark.